Build 11: December 2024 Update

The WW&F Build 11 volunteers have been as busy as Santa constructing our new steam locomotive! Hark, that’s Harold riveting!

Gordon Cook has been making 3-D models of the various components for locomotive 11. Here is a full rendering.

Now if Santa could only bring us a big enough 3-D printer, we’d be done with the locomotive by now! (But what fun would there be in that.)

Our latest Build 11 work session was held November 4-6. We’re continuing work on the forward suspension components. Jason Lamontagne completed the last welding operations on the main equalizer.

Harold Downey completed boring, drilling and reaming the holes in the lead truck and main equalizers.

Rick Sisson, Joe Monty, Harold Downey and John Pierce pressed bushings into these holes which will receive pins when the entire forward suspension system is assembled. We used both the bench arbor press and….

…this Baldwin 100 ton press which was just commissioned with Josh Recave’s assistance.

Yes, Baldwin as in Baldwin Locomotive Works. In later years, BLW produced tools as well as locomotives and we’re thrilled to be putting this machine to use.

Rick Sisson and John Pierce also bored and reamed all the spring hangers using our enormous radial arm drill which was well suited for the task.

We will have all the equalizers and spring hangers available for final assembly for the next Build 11 work session which starts TOMORROW 12/12/2024 and runs through Saturday. Stop in and see the progress – new volunteers with shop skills are most needed to keep the project “on track”.

Meanwhile, Quentin Bethune and Gordon Cook continue to fabricate the forward suspension pins needed for final assembly.

New volunteer John Pierce was tasked with drilling and reaming the remaining holes in the lead truck frame. Next, we’ll fabricate fitted bolts and complete the lead truck assembly.

With less than a month left, our 2024 fundraising has almost concluded. To date, we have received $65,716 – an impressive 131% of the $50,000 goal for 2024! Remember, you can still donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to: www.build11.org.

Wishing a Merry Christmas and a steamy New Year to all our friends, donors, and followers from the Build 11 team.

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: November 2024 Update

Our latest Build 11 work session was held October 11 -14 coincident with the WW&F Ry Fall Work Weekend. On Saturday, Joe and Jay Monty manned the torches to heat the transverse equalizer so that we could form the “ears” on each end. Rick Sisson, Bill Steussey, Joseph Gilbert, and Joe and Jay drove our forming tools with a sledgehammer to spread the ears which we later compressed with the flanging machine to form the proper geometry.

Here we see a photograph of the first completed end: Harold Downey directed the heating operation (It’s difficult for the torch bearers to clearly see what they’re doing) and Harold positioned the forming tools for the sledge bearers.

We used our lunch break to let the equalizer cool enough so that we could repeat the process on the remaining end.

We also drilled the forward frame pedestals for the bolts that will hold the driving box shoes and wedges in place. Rick coordinated this effort and was assisted by Bill and Gordon Cook. We mounted Bob Longo’s right-angle mag drill to a 90 degree angle block to drill holes parallel to the top of the frame using our favorite annular cutters.

We have purchased all the Oilite® bronze bushings required to fit up the forward suspension system components. Joe and Jay turned several of these to a shorter length for us because they were not commercially available.

Gordon and Rick were able to assemble the components needed to form our tramming tool. These parts were designed by Jason Lamontagne and were laser cut and shipped to us. The design allows very precise fore-and-aft positioning of the shaft upon which trammel points are fastened and rotated. When the shaft is properly positioned, the trammel point will just touch the tram wire in both the forward and rear rotations. This indicates that the rotating shaft is exactly perpendicular to the tram wires, which are precisely located on the cylinder center lines. The next step will be to mark the shoes and wedges with the trammel points and to record the distance from each shoe and wedge to the tram wire. These measurements will be used to complete the machining of the shows and wedges.

Quentin Bethune brought the lead truck frame back to the shop; Quentin completed the machining operations begun by Noah MacAdam – both in their home shops! Harold and Rick spent a good number of hours aligning and holding in place the lead truck components and then aligning the lead truck frame within the complete assembly. The next step will be to match drill the lead truck frame to the remaining components.

Quentin was also able to rough machine several pins for the forward suspension system. He will finish these and cut threads on them in his home shop.

Meanwhile, our 2024 fundraising is continues! To date we have received $54,045 – 108% of the $50,000 goal for 2024!!!! Remember, you can still donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to: https://www.build11.org/ All gifts above our 2024 goal will be used to accelerate the construction of the locomotive.

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: October 2024 Update –

We’ve been cooking up a brand new steam locomotive!

Here we are heating the lead truck equalizer during our Aug 13-15th work session. Gordon Cook, Harold Downey and Rick Sisson again used our flanging machine to form the “ears” at the end of the lead truck equalizer.

Harold had prepared the end of the equalizer by milling a ½” slot. We then heated the area, clamped the equalizer in the flanging machine and used a sledge hammer to drive a forming tool that we designed and assembled into the slot.

After a succession of heats we completed the forming operations.

After allowing the equalizer to cool overnight, Joe Monty drilled and bored the hole that will receive a pin connecting the equalizer to the lead truck pivot pin.

Quentin Bethune was able to turn the lead truck pivot pin bushing, another component of the lead truck suspension.

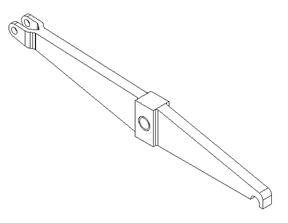

Finally, Jason Lamontagne welded bosses to the lead truck lower radius bar. Harold machined these and Harold, Gordon and Rick match drilled the lead truck pedestals to the lower radius bar.

Harold machining the lead truck lower radius bar.

During our September 10-12 work session, Gordon Cook brought components he had machined at home which will enable us to tram the locomotive. This entails running a wire from the center of the bore at the front of each cylinder to a point located at the rear end sill backer plate. The wire will be carefully aligned with the center of the cylinder bore and will provide a reference to locate, and machine, the driving box shoes and wedges.

The front of the cylinder. The wire will pass over the small brass pulley and be tensioned by fastening a weight to the wire.

At the rear of the frame a small brass bushing is used to precisely locate the taut wire.

Gordon also spent some time drilling holes in the forward frame to attach driver brake hangers.

Harold Downey and Rick Sisson were able to mill one of two slots in the transverse equalizer. These slots will be hot formed to form the required “ears” as we did last month for the lead truck equalizer.

Qunitin Bethune brought to the shop the lead truck pin that he machined at home. So, we had to tie the lead truck equalizer to the lead truck pin and bushing.

Rick Sisson drilled and reamed holes for, and attached, the lower radius bar cross tie. Noah MacAdam used his large mill to accurately place mounting holes in the lead truck frame. We positioned the lead truck frame on the lower radius bar to check the fit. Quentin will perform additional machining operations on the lead truck frame in his shop.

Harold and Rick formed the perimeter angle curved corners. Rick prepared the pieces and clamped them in position for welding. The perimeter angles are the last components included in the rear frame.

We are currently requesting quotations from foundries for piston, crosshead and rear couple components to be delivered next year. In order to expedite production, we are asking the foundries to source 3D printed molds which will add to our costs. Our 2024 fundraising is continuing! To date we have received $48,668 (97% of the $50,000 goal for 2024). Remember, you can still donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to: www.build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: Major Donation Received

Today, we are pleased to announce a major donation towards the completion of WW&F Locomotive 11, a new-build reconstruction of WW&F no. 7, which was scrapped in the 1930s.

Two lifetime fans of the Maine two-footers, Gordon Fay and George Bartholomew, have pledged $15,000 to get the Build 11 project on track for completion. This means that we only need $2800 to make our 2024 fundraising goal! More importantly, we can now start outsourcing some of the work, allowing us to complete the locomotive sooner.

How can you help?

The Build 11 challenge coin ($11 donation) is available in person at our gift shop or online at: https://giftshop.wwfry.org/product/challenge-coin/661?cs=true

Or want a REAL challenge? Sign up to volunteer on the project! We are in need of additional craftsmen and machinists to help fabricate and assemble the locomotive. Inquire at info@wwfry.org or come by our open house on Saturday, Sept. 14th at 10am.

Author Michael Torreson has donated 200 SIGNED copies of his book: “Maine’s Two-Footer Railroads: The Linwood Moody Collection” to be sold in our gift shop (online or in person) with 100% of the proceeds going to fund locomotive no. 11!

Get your signed copy (for a donation of $24.99) at: https://giftshop.wwfry.org/product/maine-s-2-er-rrs-the-linwood-moody-collection/696

Speaking of signing… sign up to volunteer at the WW&F at: https://wwfry.org/all-activities/volunteer/

The “builder’s plate” is like the locomotive’s birth certificate. It is typically mounted on the side of the smokebox indicating where and when the locomotive was built. We have replicated WW&F no. 7’s builder’s plate in two forms to be used as fundraisers for locomotive no. 11.

This mini “builder’s plate” is 3-D printed and available for a donation of $110. Get yours by making an online donation at: https://giftshop.wwfry.org/product/miniature-builders-plate/809?cs=true

Or, if you want something really big…

Our beloved, late Build 11 volunteer, Wayne Laepple oversaw the production of a limited number of full-size cast replica builder’s plates of locomotive #7. We still have a VERY FEW of these still available for donations of $1100 (or more.)

Join the “31692 Club” and proudly display this plate in your office, den, or train room. Please contact us at info@wwfry.org if you would like to make a $1100+ gift and wish to receive this “thank you” gift. Or, mail a check to WW&F Railway Museum, PO Box 242, Alna, ME 04535 and be sure to indicate your donation is for Build 11 and that you would like a builder’s plate.

Not into extra stuff? Be like Gordon and George and donate any amount online at www.build11.org – or use the address above.

Together, we can meet the challenge to accelerate locomotive 11’s fabrication and assembly. Thank you for your interest and support!

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: August 2024 Update

Our latest Build 11 work session was held July 9 -11, 2024. Gordon Cook, Harold Downey and Rick Sisson spent a great deal of time preparing the main equalizer pedestals for installation. These components are located on the forward frame and support the main equalizers which pivot about a 2” pin.

We then turned our attention to the main spring hangers. These were again hot formed by bending to the correct shape using our flanging machine. We had previously formed one hanger during our last work session and completed the remaining three during this session. This is very exacting work because we have to ensure the holes at the end of each leg are precisely aligned to accept the pin that will join them to the main equalizers.

Finally we employed the entire Build 11 team to rivet the main equalizer pedestals to the forward frame.

Our Hanna squeeze riveter is suspended upside down to reach the bottom rivets. This is the first time we’ve had the Hanna positioned this way but it did a good job nonetheless.

Jason Lamontagne was enlisted to drive the top pedestal rivets by hand, and we see the finished result below:

Meanwhile, our 2024 fundraising is continuing! To date we have received $24,553 (49% of the $50,000 goal for 2024). Will you be the one to contribute $447 to bring us halfway to our 2024 goal?

You can donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to: www.build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: July 2024 Video Update

Build 11 team members Gordon and Rick were working on the locomotive today, so instead of a detailed written progress report, see for yourself how the project is progressing!

Learn more and contribute at: www.build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: June 2024 Update

Here is a somewhat tardy report from the Build 11 work session that was held June 8 -11.

Quentin Bethune and Gordon Cook heat shrunk the previously machined sleeves onto the second axle on Saturday. Quentin then machined both sleeves on the axle. Both rear truck axles are now ready to receive wheels. On Sunday Harold Downey, Gordon Cook and Rick Sisson applied Epifanes metal primer to all the components of the rear truck frame. We have partnered with Epifanes to provide finishes for our Coach 9 project and they are providing us great products and support. Once the primer has dried a black finish coat will be applied before final assembly of the rear truck.

Harold determined that some of the bearing brass babbitt had too many voids so he reclaimed the babbitt from the affected brasses so that they could be poured again.

Alan Downey completed the rough machining of the shoes and wedges which will provide a sliding interface between the forward frame and the driving axle bearing boxes. The interior of both shoes and wedges will be machined next making them ready for tramming in an upcoming work session. Gordon has been designing a fixture to ensure accurate tram line positioning.

On Monday Jerry and Carlos Steinke set up the wheel press and they, Quentin Bethune and Jason Lamontagne assisted by Noah McAdam, Harold Downey and Gordon Cook successfully pressed the wheelsets onto the rear truck axles. This is a major milestone toward assembling the rear truck and your Build 11 team is ecstatic!

Rick prototyped a tooling setup to enable us to drill the forward frame for shoe and wedge attachment bolts. We will be able to clamp a 3-sided bench block to the frame and attach Bob Longo’s right angle mag drill to that block, thus ensuring a properly aligned hole in both horizontal and vertical axes. The setup was checked to verify that all (3) holes could be drilled in the frame without interference. We will be boring these holes once the shoes and wedges are ready.

Rick and Gordon drilled and reamed the equalizer pedestals and forward frame preparing these components for riveting. Noah assisted by machining custom transfer punches to transfer hole positions from the frame (already drilled) to the equalizer pedestals.

On Tuesday Joe Monty, Gordon and Rick formed the first of four spring hangers. Noah had previously welded hole bosses on each of these components in his home shop. As with every new component we fabricate we had to develop specific methods to achieve the required geometry. This was the first time we used the flanger toggle to square up the end of the spring hanger and this approach worked quite well.

Our 2024 fundraising is continuing! To date we have received $22,509 (45% of the $50,000 goal for 2024). Remember, you can still donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to www.build11.org. A very limited number of replica builder’s plates of WW&F locomotive #7 remain available for one-time donors of $1100; contact us for details!

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: The Squeeze is ON!

The team building locomotive 11 have been hard at work over the last several days, so a formal work update will be coming soon. Here’s a sneak preview of the accomplishments this month – one of the tender truck wheels being fitted to its axle!

Learn more and contribute at: www.build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: May 2024 Update

Our last Build 11 work session was held April 25 – 28 during our Spring Work Weekend. Between sessions Harold Downey has continued working on the rear truck frame – the arch bars and journal boxes have been bolted in. We plan to prime all the components before final assembly.

Quentin Bethune brought back the lead truck center casting he machined at home. He did a great job and those bolts he made are exceptional!

Harold, Bill Steussy, Joe Monty and Rick Sisson used our flanger to hot form the main spring staples. We eventually settled on three heats and squeezes in the flanger to form the correct shape in three orthogonal planes. Joe was able to fashion a sort of enclosure using ceramic fiber blankets which accelerated our torch heating – very clever! Once again, this was a learning process for us – the first staple took us between 4 and 5 hours to get right; the remaining three staples took about an hour to complete. This is becoming a recurring theme for your Build 11 team.

We turned our attention next to hot forming the equalizer pedestals. We used the same processes to form these as the main spring staples.

Since we were on a roll, we continued to form the brackets that support the driving box wedge bolts. Jason Lamontagne had built a set of dies (used for locomotives 9 and 10) that we used to hot form our brackets. We were able to heat our material in our propane forge. Before and after photos are shown below:

We had some hand work to do after pressing our material to straighten the ends.

Harold was able to pour babbitt into the bronze truck bearings that we had cast for us. Babbitt is a lead, tin and antimony alloy that provides an anti-galling bearing surface.

In an earlier Build 11 work session we attempted to press the rear truck wheels onto their axles, machined by Quentin. Because the wheel bores lacked lead-in, or an entrance taper, both the axles and wheels were scored when we pressed the wheels on. We disassembled the wheelsets, diagnosed the root cause, and developed a corrective action plan. Our solution entails reducing the axle diameter, increasing the wheel bore diameter and fitting a sleeve between the axle and wheel. Gordon Cook and new volunteer Gorham Rowell turned the inside of the sleeves to the prescribed diameter; Quentin then turned the axles to provide a 0.005” interference fit to each sleeve.

Gordon was able to heat two sleeves in the WW&F Ry barbeque (one at a time) to expand the sleeve so that each sleeve could be dropped over the corresponding axle. Because the barbeque was used by the kitchen crew during our Spring Work Weekend we had to wait until lunch was served. Soaking each sleeve at a temperature between 400 and 500 degrees Fahrenheit allowed an easy slip onto the axle as shown below:

Finally, we want to thank our great friends at the East Broad Top Railroad for donating two original Eames vacuum pots to us. The crews of the EBT discovered these extremely rare objects in their lumber shed! These likely came from some of the earliest EBT locomotives before conversion to air brakes. While the WW&F Ry is constructing new vacuum pots for our rolling stock, these unique pieces will be a historic addition to our #11. Gordon is measuring these vacuum pots so that he can design mounting brackets specifically for these pieces. We’ll be posting an update on these when they get attached to the frame.

Our 2024 fundraising is continuing! To date we have received $21,026 (42% of the $50,000 goal for 2024). Remember, you can still donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to: www.build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: April 2024 Update

A springtime snowstorm did not slow down our progress this month; an abbreviated Build 11 team was back for our April 3-5 work session. Between sessions Harold Downey continued assembly of the rear truck frame.

Gordon Cook spent part of the day Wednesday working on locomotive 9’s injector with Roger Whitney and Jason Lamontagne. Later Gordon worked on machining one of the sleeves for the rear truck axles. Gordon tried to return on Thursday but was unable to reach the museum during the snow storm due to fallen trees blocking route 218!

Rick Sisson spent the day Wednesday completing the anvils that will be used as tooling to form the main spring staples, equalizer pedestals and main spring hangers:

Thursday Rick was able to fillet the driving axle jaws in the forward frame. The jaws have to be rounded to accommodate the inside corners of the driving box shoes and wedges. We were able to borrow a 30 degree plate beveling machine from our friend Brian Fanslau of Maine Locomotive and Machine Works in Alna, Maine. Using this tool, we were able to remove most of the material in two passes, as shown in the drawing. We then removed the remaining material with a hand grinder and finished the surface with a file.

Brian’s plate beveling machine saved us an enormous amount of time; we used to remove all the material with a great number of passes with the hand grinder.

The boss will be welded to the lower radius bar when fitting up the pedestals and journal boxes.

On Friday afternoon, Jason and Rick completed forming the lead truck spring hangers. When formed in our flanging machine during the last session, the legs sprung back as we anticipated. We were able to reheat the corners and square up the hangers in the bench vise while holding the pin holes in alignment with a shoulder bolt. Below we see before (left) and after (right) examples:

We look forward to seeing everyone at our next work session scheduled during our Spring Work Weekend, April 26-28. We invite you to stop by, say “hello” to the Build 11 team and let us show you what we’re up to!

Our 2024 fundraising is continuing! To date we have received $15,161 (30% of the $50,000 goal for 2024) – which includes a $2000 anonymous donation made today! Remember, you can still donate directly by check to the museum (which is preferred for large donations), use a credit card to donate through the gift shop, PayPal, or you can go to: build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: March 2024 Update

The Build 11 team was back for our March 5-7 work session.

We had a number of team members working on projects during the March 5-7 work session: Harold Downey and Rick Sisson used our flanger to complete all the bending operations described in the captions. Harold also machined the 180 degree bends to finished dimensions. Rick, Bob Longo, Jason Lamontagne and Joe Monty fabricated the tooling required to bend the spring staples and spring hangers. Quentin Bethune and Gordon Cook kept our lathes busy.

Meanwhile, between the February and March work sessions, Harold Downey machined the lead truck pedestal surfaces to fit the lead truck radius bars and journal boxes.

One goal of the March work session was to compete the 180 degree bends on the ends of the lead truck lower radius bar and the rear truck arch bars. This mutli-step process entailed 1) heating and bending each bar 90 degrees in our flanger, 2) reheating the bar, clamping it in the flanger and striking the end with a sledge hammer to increase the bend to roughly 135 degrees and 3) reheating the bar and “squishing” it in the flanger until the full 180 degree bend is achieved.

After hot flanging the bar to 90 degrees Harold is reheating the bend so that it can be extended.

Actually, Harold is extending the 90 degree bend closer to 135 degrees so that it can be flattened in the flanger, here being used as a giant vise.

The 180 degree bend is complete. We performed a total of six 180 degree bends this session.

Harold machined the 180 degree bends in the lower radius bar to the finished dimension on our vertical mill. He also machined the arch bar bends to the finished dimensions.

Another goal of this work session was to form the lead truck spring staples and spring hangers, indicated by blue text, below:

We fabricated separate bending forms (anvils) for each and realized the process we had envisioned wasn’t going to work. We then fabricated a keeper that our flanger could press down on the material (secured to the anvil) to bend our material to conform to the anvil while keeping the two legs parallel.

Although we spent 2 days fabricating the tooling to produce just 6 components, we are extremely pleased with the resulting parts. This investment in time and talent paid off handsomely for us.

Meanwhile, Quentin Bethune was able to bore the wheel centers for the rear truck axles using a clamping fixture fabricated by Jason Lamontagne. This was painstaking work that will ensure a precise fit. Quentin was able to complete 4 wheels in just two days work.

Gordon Cook started to use our Victor lathe, was setting up some work and the lathe refused to resume operation. Gordon studied a schematic diagram stored in the machine and while tracing the wiring with Brandan Barry’s help found 3 loose wires, which he suspects were not properly connected at the factory.

Our 2024 fundraising is continuing! To date, we have received $ 11,486 (23% of the $50,000 goal for 2024). Remember, you can still donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to: build11.org

Thank you from all of us for your continued interest and support!

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: February 2024 Update

The Build 11 team was back for our February 4-6 work session. Harold Downey, Joe Monty and Rick Sisson completed hot bending the lead truck pedestals using our flanging machine. The shorter bends were performed during the January work session. These components will be machined to ready them for assembly.

Meanwhile, Harold finished machining the rear truck swing link hanger castings. These are mounted to the top of the rear truck transoms and support, through the swing links, the spring plank.

During the time between work sessions Alan Downey machined the poling pocket castings. These will be mounted on either side of the pilot beam.

Alan Downey also machined the rear truck center plate which will be bolted to the bolster. Joe Monty drilled mounting holes in the spring plank.

After a morning of preparation Harold, Rick, Jason Lamontagne, Gordon Cook and Dave Buczkowski were able to rivet the rear truck assembly. Harold had developed a pneumatic buck which we used to back up each rivet as it was driven. This truck assembly uses 24 rivets which were done in one day.

Once the riveting was done we test fit the rear truck assembly. Gordon had brought up the swing link pins that he made in his home shop.

Meanwhile, Noah MacAdam has been busy in his home shop machining the lead truck bearing boxes and rear cylinder heads.

Noah has started work on the crosshead guide assemblies utilizing the precision milled bar stock we recently received. His next step will be to machine the spacer blocks that capture the crosshead guide ends and mount to the rear cylinder heads and guide yoke.

Our 2024 fundraising off to a great start! To date we have received $8,737 (17% of the $50,000 goal for 2024.) Remember, you can still donate directly by check to the museum, use a credit card to donate through the gift shop, PayPal, or you can go to build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team

Build 11: January 2024 Update

The Build 11 team, after enjoying a holiday break, was back at it again during our January 2-4 work session. Quentin Bethune completed polishing the first rear truck axle journal bearing surfaces using a tool post grinder generously donated by Noah MacAdam.

Meanwhile, Gordon Cook, Rick Sisson and Jason Lamontagne completed installation of the lead truck radius bar cross tie. This effort included drilling the through hole for the radius bar retaining pin, drilling and tapping 4 holes in the underside of the forward frame to mount the cross tie, and finally countersinking the through hole to receive the retaining pin. This work alone took us almost two days to complete.

Harold Downey assisted us in cold flanging the 7/8” thick radius bar. This component looks like a gigantic hairpin and required four bends, which came out rather well. We used a purpose built anvil placed in our flanging machine to form these bends. We start the bend and remove the work piece when we judge the bend to be close to the desired angle. Then we use a plywood template to quantify the achieved bend angle, reinsert the work piece in the press, and repeat the process a number of times until the proper bend angle has been formed. On occasion when we have over bent the work piece, we’ll have to remove the work piece, flip it over, and try to bend it back to the correct angle.

We need to form four lead truck pedestals – these are C-shaped components formed from 1” by 3” bar stock, about 2 feet long. We have to heat these with an oxygen – propane mixture until the area is glowing (orange), move them carefully (the work piece gets really hot) to the anvil and begin the bending process as described above. We were able to form the first bend on each of the 4 pedestals during this work session; we’ll form the remaining bends during our next work session.

Noah has started to machine the rear cylinder heads in his home shop. This is the first step in installing the crosshead guides on the locomotive.

Noah has also completed the lead truck bearing boxes – the boxes have been bored and machined to accept the bearing retainers.

Gordon has machined the lead truck spring hanger pivots and pins in his home shop and brought them to Sheepscot.

Quentin has brought home the lead truck swing links, where he will machine the holes, insert the bushings and drill oil holes:

Here’s an illustration of the components we’ve worked on this session.

2024 FUNDRAISING GOAL ANNOUNCED!

With 2023’s goal surpassed with $64,111 raised, we are moving forward with a $50,000 goal in 2024 to make “Wheel Progress”. Learn more, and contribute, at build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team