Our latest Build 11 work session was held on September 8-10. Harold Downey, Gordon Cook and Rick Sisson set up our crankpin press to, you guessed it, press crankpins into our driving wheelsets.

In the following photo, you can see how the crankpin press extension was specifically designed to fit between the counterweight and wheel. The rest of the crankpin press was used without modification. You can see the crankpin partially pressed into the counterweight as well.

We successfully pressed all 4 crankpins during our work session.

The completed wheelsets (waiting for driving boxes):

Joe Monty joined us and continued work on the rear coupler assembly. He fabricated the eye bolt at home and installed it into the coupler body.

Joe returned home and completed the eye bolt (note the threaded end and nut).

Harold, Gordon and Rick formed the last eccentric rod “U” end after completing the crankpin installation.

Mountain Machine Works has completed the machining of the crosshead guide subassemblies. These are much bigger, and heavier, than you’d guess from the photo:

We have delivered the driving box crown brasses received from New England Castings in Standish, Maine to Mountain Machine Works so that they can begin their work on the driving boxes. We expect to receive complete driving boxes late this year.

Harold had begun machining the driving box cellars between work sessions:

Gordon spent the last day of our work session machining two sides. Since our last work session, Harold has completed the driving box cellars except for final machining to width after the driving boxes are done.

Again, since the last work session, Quentin Bethune has finished the keyways in the eccentrics. These are absolutely beautiful:

And for a comparison, these are the rough castings Quentin started with:

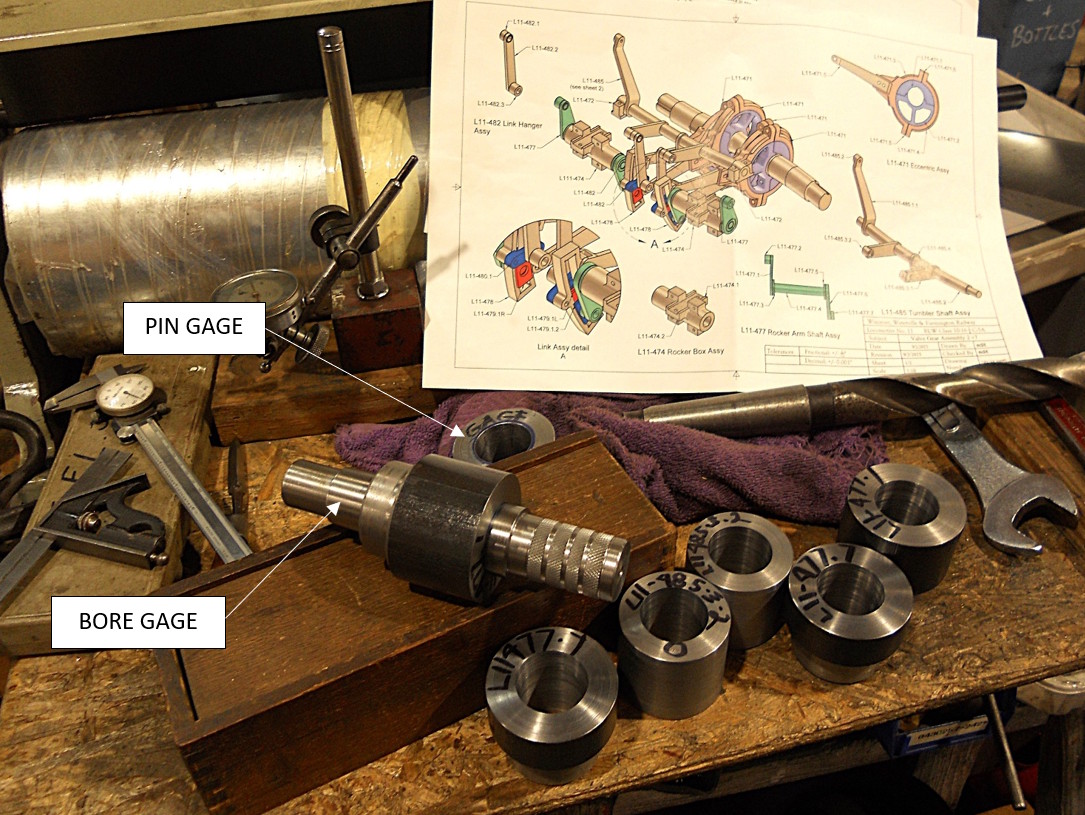

Earl Leavitt has been busy since the last work session as well. He’s been concentrating on the valve gear parts needing tapered holes. He started by making a set of gages specifically for the 1 3/8″ pins and bores.

Earl next set up our Victor lathe to do the internal taper bores on all the rocker arm bosses as well as the bosses for the link lifter arms. All the machining for the upper and lower rocker arms as well as the lifter arms is now complete.

Earl has pressed all the lifter and rocker arm parts together. They’re now ready for welding:

…and thank YOU for giving more than 111% to this project! In 2025, our friends and followers have donated an astounding $137,562 towards Build 11 – 114% of our $120,000 goal (for 2025.) All additional funds are being used to ensure the locomotive is on the rails as quickly as possible.

Learn more and contribute at www.build11.org

Thanks for your continued support and interest in the WW&F!

The Build 11 Team